- Paddle, Mixing, Stainless Steel (see Mixing Paddle, Stainless Steel)

- Pail with Bottom Chime, Stainless Steel

- Pail with Cover, Stainless Steel

- Pail with Pouring Lip, Tilt Handle, Stainless Steel

- Pail with Tilting Handle, Stainless Steel

- Pail, Tote With Cover, Stainless Steel

- Pail, Utility, Stainless Steel

- Pan, Stainless Steel

- Pet Cock (see Valve, Cock (Pet, Sampling, Tee Handle and Three Way), Stainless Steel)

- Pitchfork, Stainless Steel (see Shovel and Pitchfork, Sanitary, Stainless Steel)

- Plate and Frame Filter (see Filter, Plate and Frame)

- Propeller, Mixer, Stainless Steel (see Mixer Propeller, Stainless Steel)

- Pump, Centrifigal, Stainless Steel

- Pump, Positive Displacement, Rotary

|

RETURN |

|

Pail with Bottom Chime, Stainless Steel |

Click on the picture for a larger image |

| T-21-156 |

13 qt, 304 ss |

| T-21-157 |

16 qt, 304 ss |

| T-21-158 |

20 qt, 304 ss |

| T-21-207 |

16 qt, 316 ss |

| T-21-208 |

20 qt, 316 ss |

|

|

| Polished inside and out to a sanitary finish. |

|

RETURN |

|

Pail with Cover,

Stainless Steel |

Click on the picture for a larger image |

| T-21-169 |

9 qt |

| T-21-159 |

13 qt |

| T-21-160 |

16 qt |

| T-21-161 |

20 qt |

|

|

| Seamless construction polished to a sanitary finish. T-304 stainless steel. |

|

RETURN |

|

Pail with Pouring Lip,

Tilt Handle, Stainless Steel |

Click on the picture for a larger image |

| T-21-201 |

13 qt |

| T-21-206 |

16 qt |

|

|

| Hemmed and soldered top rim. Bale handle. T-304 stainless steel only. Polished to a sanitary finish |

|

RETURN |

|

Pail with Tilting

Handle, Stainless Steel |

Click on the picture for a larger image |

| T-21-151 |

13 qt, T-304 ss |

| T-21-153 |

16 qt, T-304 ss |

| T-21-155 |

20 qt, T-304 ss |

| T-21-203 |

16 qt, T-316 ss |

| T-21-205 |

20 qt, T-316 ss |

|

|

| Available with bottom chime. Please inquire. |

|

RETURN |

|

Pail, Tote With Cover, Stainless Steel |

| T-30-148 |

19-3/4 qt, 9-1/2" dia x 16" high |

|

The pail has a bail handle and lower tilting handle. The cover hangs on the side of the pail for added convenience and sanitation. Seamless construction. Polished to a sanitary finish. T-304 stainless steel. |

|

|

RETURN |

|

Pail, Utility, Stainless Steel |

Click on the picture for a larger image |

| T-21-149 |

9 qt, T-304 ss |

| T-21-150 |

13 qt, T-304 ss |

| T-21-152 |

16 qt, T-304 ss |

| T-21-154 |

20 qt, T-304 ss |

| T-21-202 |

16 qt, T-316 ss |

| T-21-204 |

20 qt, T-316 ss |

|

|

| Seamless construction. Polished to a sanitary finish. |

|

RETURN |

|

Pan, Stainless Steel |

Click on the picture for a larger image |

| T-30-244 |

Straight-sided, 7-7/8 qt |

| T-30-245 |

Straight-sided, 13-1/2 qt |

| T-30-246 |

Straight-sided, 20 qt |

| T-30-247 |

Straight-sided, 4-1/8

q |

| T-30-248 |

Straight-sided, 6-3/4 qt |

| T-30-249 |

Straight-sided, 10-1/8 qt |

| T-30-250 |

Straight-sided, 1-7/8 qt |

| T-30-251 |

Straight-sided, 3-1/8 qt |

| T-30-252 |

Straight-sided, 4-5/8 qt |

| T-30-253 |

Loaf, 4 lbs |

| T-30-254 |

Round, 12 qt |

| T-30-255 |

Round, 24 qt |

| T-30-256 |

Round corner, 1-1/4 qt |

| T-30-262 |

Round corner, 1 qt |

| T-30-263 |

Round corner, 1-5/8 qt |

| T-30-264 |

Round corner, 2-1/2 qt |

| T-30-270 |

Bake/roast, 3-1/2 qt |

| T-30-271 |

Bake/roast, 4-3/4 qt |

| T-30-272 |

Bake/roast, 6-1/2 qt. |

|

|

| Seamless, sanitary construction. T-304 stainless steel. |

|

RETURN |

|

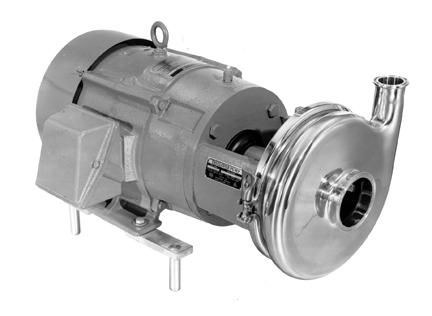

Pump, Centrifigal, Stainless Steel |

Click on the picture for a larger image |

| T-17-155 |

1-1/2" inlet |

| T-17-142 |

2" inlet |

| T-17-157 |

2-1/2" inlet |

| T-17-146 |

3" inlet |

| T-17-158 |

4" inlet |

| T-17-150 |

6" inlet |

|

|

Tri-Clover stainless steel pumps are designed to handle the pressure, capacity and temperature problems common in food and beverage processing applications. Centrifugal pumps are best suited to low viscosity fluids, 500 cps or less.Positive rotary pumps are recommended for products with high viscosity or suspended solids. Sanitary, clean-in place pumps are available. Pumps are mounted with motors at additional cost.

When requesting a quotation or recommendation, please provide answers to as many of the following questions as possible.

1. Material to be pumped

2. Viscosity

3. Temperature

4. Pipe size

5. Number of elbows in the line

6. Distance to be pumped - vertical and horizontal

7. Discharge pressure

8. Hours used per day

9. Phase/cycle/voltages |

|

RETURN |

|

Pump, Positive Displacement, Rotary |

Click on the picture for a larger image |

| T-17-131 |

3 gpm, 1" inlet and outlet |

| T-17-143 |

10 gpm, 1-1/2" inlet and outlet size |

| T-17-145 |

25 gpm, 1-1/2" or 3" inlet and outlet |

| T-17-147 |

60 gpm, 2" or 3 " inlet and outlet |

| T-17-149 |

125 gpm, 2-1/2" or 3" inlet and outlet |

| T-17-151 |

300 gpm, 4" or 6" inlet and outlet |

|

|

Positive rotary pumps are designed to provide optimum pumping capacity of hot, tacky or viscous products. T-316 stainless steel construction. They are mounted with motors at additional cost. Relief covers are standard and provide a positive means of protecting lines and equipment when pressures build up.

When requesting a quotation or recommentation, please provide answers to as many of of the following questions as possible.

1. Material to be pumped

2. Viscosity

3. Temperature

4. Pipe size

5. Number of elbows in the line

6. Distance to be pumped - vertical and horizontal

7. Discharge pressure

8. Hours used per day

9. Phase/cycle/voltage |

|

RETURN |

|

|

|